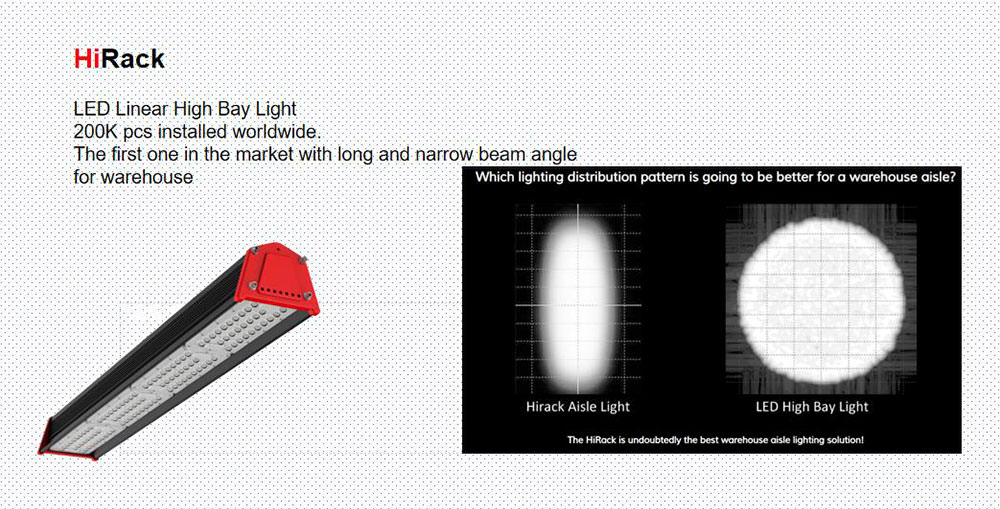

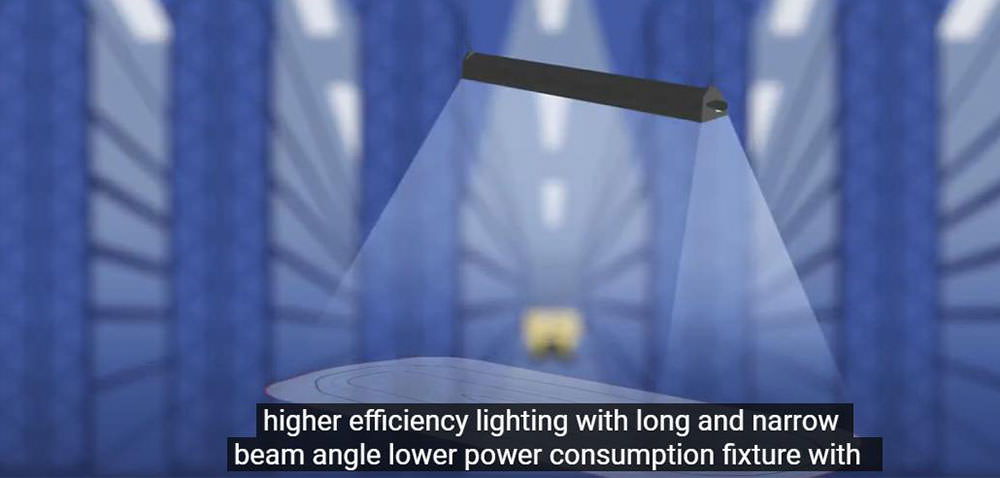

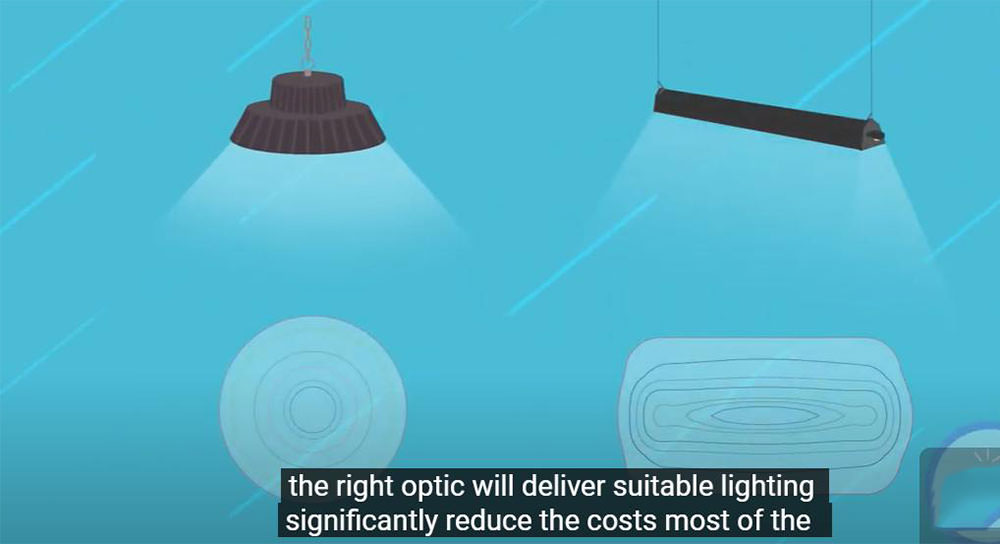

When searching Google Images for warehouses, we will find a huge market potential for warehouse lighting. A warehouse is typically divided into docking areas and racking areas. The common high bay light with a round beam angle is available for docking areas. However, the racking area requires much higher efficiency lighting with a long and narrow beam angle. A low power consumption fixture with the right optic will deliver suitable lighting and significantly reduce the costs.

Most of the time, there are no people or forklifts in the racking area, and skylights are installed in the warehouse. Above all, proper warehouse lighting is good for energy saving. There are various individual controls and motion sensors available in the market. However, the fixtures always turn on instantly when the sensor is activated by someone passing nearby. As a result, drivers often complain about the dazzling light, as the individual motion sensor is not human-centric.

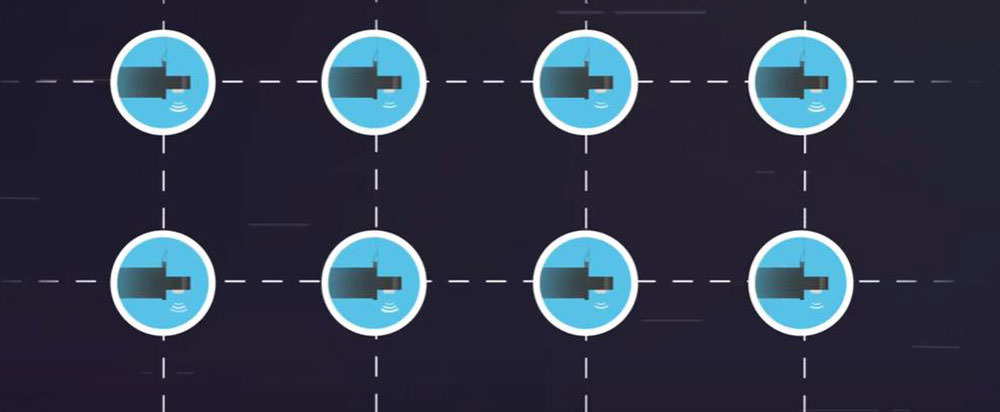

AGC provides a lighting control solution that takes human feelings into consideration. For instance, the HiRack family offers various options for power and beam angle, making it the perfect solution for aisles in warehouses. When equipped with intelligent control, all the fixtures can be easily grouped without any extra wires, gateways, or complicated software on phones or computers. With a remote control, anyone can easily complete the grouping process. For example, we can connect Fixture No. 123 to Group One, Fixture No. 234 to Group Two, and Fixture No. 345 to Group Three. When Fixture No. 1 turns on and its sensor detects the motion of a forklift in the aisles, Fixtures No. 2 and 3 will also be switched on due to the grouping function. When the sensor of Fixture No. 2 detects movement, it will activate the sensors of Fixtures No. 3 and 4 to turn on the lights. The fixtures are always turned on before the forklift approaches nearby.

The drivers in forklifts will feel comfortable as the fixtures are turned on in order before their arrival. The grouping function will undoubtedly help increase warehouse management efficiency and accuracy rate. Furthermore, the daylight harvesting sensor will control the fixtures to work at a tempered brightness, such as 20%, since the skylights provide sufficient lighting during the day. By pressing the control aim at the fixture, you can download information displayed on the controller screen, including the brightness of the fixture. With the special sensor optic in the fixture, movements from the next aisle will not easily activate it, avoiding mutual interference better than the common microwave sensor.

AGC's intelligent control system is based on the Zigbee protocol. However, compared to common Zigbee or DALI control systems, AGC's intelligent control system utilizes blockchain technology and operates as a mesh network without a centralized data center or master node. Each node in the network acts as a relay for the next node, ensuring that if one node fails, it does not affect the entire network. Additionally, the communication distance is much longer than Bluetooth technology.

Also, we would like to provide two video links as a reference on how to easily achieve group control for lighting.

For more information, contact us today