Lighting is a key factor for manufacturing operations. It affects the visibility and safety of workers, as well as the efficiency of the processes. As the the manufacturing industry adopts the Internet of Things (IoT) technologies to improve productivity and performance, operators are always looking for ways to optimize their processes and benefits from the industry 4.0. One of the emerging solutions is the IIoT (Industrial Internet of Things) lighting, which is a subset of IoT lighting that focuses on the industrial applications.

IIoT lighting uses integrated lighting systems with a network and sensors to provide smart lighting that can maximize energy savings, improve productivity, and maintain safe and comfortable light levels. In this blog, we will explain what IIoT lighting is and how it can help manufacturers enhance manufacturing efficiency.

What is IIoT lighting

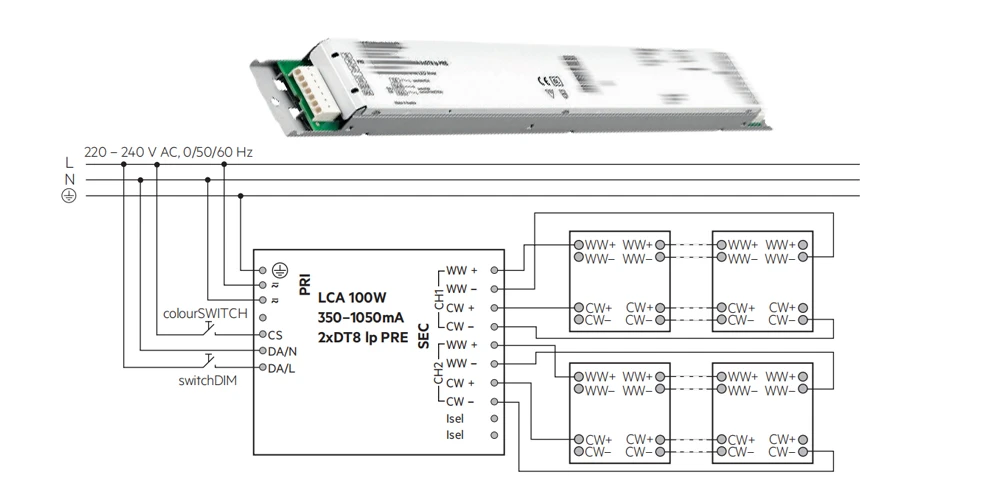

IIoT stands for Industrial Internet of Things. It refers to a system of interconnected devices that can collect and exchange data through the internet. One of the applications of IIoT is smart lighting, which uses sensors and wireless communication to create a network of intelligent lighting devices. These devices can adjust their brightness and color according the to the environment and user preferences. They can also communicate with other devices and provide valuable information for optimizing processes and improving productivity.

IIoT lighting has many benefits over traditional lighting systems, such as energy efficiency, cost savings, safety and security, and quality and performance. It can be applied to various sectors, such as manufacturing, logistics, and mining. IIoT lighting is a type of smart solution that can transform the way we use light in various sectors. It can provide better lighting quality, higher energy efficiency, lower operating costs, and more data insights.

4 Ways IIoT Lighting boosts manufacturing efficiency

IIoT lighting is a smart solution that uses the Industrial Internet of Things (IIoT) to connect and control lighting systems in various sectors. IIoT lighting can help manufacturers improve efficiency by improving energy efficiency, real-time monitoring and control, preventive maintenance, and OEE monitoring.

Improve energy efficiency

Lighting is one of the major sources of electricity demand and carbon footprint. According to a report by the International Energy Agency (IEA), lighting accounts for about 15% of global electricity consumption and 5% of global CO2 emissions. Therefore, improving lighting efficiency can have a significant impact on energy savings and climate action.

IIoT lighting can improve energy efficiency, which means it can use less energy to provide the same or better lighting service. IIoT lighting improves energy efficiency through the use of advanced sensors and automation. The lighting system can be programmed to automatically adjust lighting levels based on factors such as occupancy, time of day, and natural light levels. For example, IIoT lighting can use sensors and software to detect when a machine is not in use and dim or turn off the lights accordingly. It can also be scheduled to provide the optimal lighting according to the production cycles and shifts. By these ways, IIoT lighting can lower electricity bills and contribute to grid stability.

Real-time monitoring and control

Real-time monitoring and control means manufacturers can collect and analyze data on lighting performance, quality, and usage, and adjust the lighting settings accordingly. This can help manufacturers optimize lighting conditions and troubleshoot issues. For example, IIoT lighting can help manufacturers monitor and control the lighting levels according to the production requirements and the worker preferences. This can improve the visibility, accuracy, and comfort of the workers, and reduce errors and defects. It can also adjust the color temperature and intensity of the light according to the circadian rhythm of workers, creating human centric lighting. IIoT lighting can also help manufacturers monitor and control the lighting quality according to the product specifications. This can ensure the consistency, uniformity, and color accuracy of the products.

Preventive maintenance

Preventive maintenance means that manufacturers can prevent downtime and failures by predicting and detecting lighting problems before they affect production. This can improve reliability, safety, and customer satisfaction.

IIoT lighting system can monitor the health and status of lighting systems, such as light life, temperature, power, voltage, current, and faults. These data can be sent to a cloud or edge platform. Manufacturers can use these data to identity and diagnose lighting issues, such as LEDs flickering, dimming, overheating, or malfunctioning. By analyzing data from sensors, factory managers can predict imminent failures and avoid high costs of unforeseen breakdowns. They can also use these data to schedule and perform maintenance actions, such as replacing, repairing, or upgrading lighting components. IIoT lighting help manufacturers prevent downtime and failures by integrating with other industrial systems, such as production machines and sensors. This way, they can coordinate and optimize their lighting and production processes.

OEE monitoring

OEE stands for overall equipment effectiveness, which is a metric that measures the availability, performance, and quality of machines and processes. OEE can help manufacturers assess and improve their productivity, reduce waste, and increase profit.

The key benefits of IIoT lighting for OEE monitoring is its ability to collect and analyze data in real time. These data can be correlated with the data from other industrial systems, such as production machines and sensors. This can provide insights into how effectively equipment is being used and identify areas for improvement. IIoT lighting systems can also be programmed to provide alerts when OEE falls below certain thresholds, allowing manufacturers to take corrective action quickly and efficiently. IIoT lighting can store and analyze data over time, creating a historical record of lighting performance and quality. This can help manufacturers identify trends and patterns that can be used to optimize processes and improve efficiency.

To conclude, IIoT lighting is a smart and sustainable solution that can boost your manufacturing efficiency in many ways. By improving energy efficiency, real-time monitor and control, preventive maintenance, and OEE monitoring, IIoT lighting can optimize your energy consumption, improve your workers’ safety and productivity, and enhance your product quality and customer satisfaction.

As more manufacturers adopt IIoT lighting solutions, we can expect to see significant improvements in productivity, profitability, and sustainability across the industry. If you are interested in IIoT lighting, please contact us. We would love to hear from you and help you with your IIoT lighting system.