Explosion-proof lights are indispensable in industries where flammable gases or liquids are prevalent, such as LNG (liquefied natural gas), LPG (liquefied petroleum gas), and CNG (compressed natural gas) plants. These facilities necessitate specialized lighting solutions capable of enduring harsh conditions and averting potential explosions stemming from electrical equipment, including lighting fixtures.

Therefore, when formulating project plans, it is crucial to understand the characteristics of the gas processing locations.

Understanding LNG, LPG, and CNG: Unveiling the Differences

Ever wondered about the distinctions between LNG, LPG, and CNG? These three acronyms all denote forms of natural gas, yet they diverge in their physical states and methods of storage and transportation.

LNG (Liquefied Natural Gas)

Transforms natural gas into a liquid state through extreme cooling (-162°C). Ideal for long-distance transport, such as by ship. Mainly employed in large-scale applications like power generation, industrial processes, and marine vessel fuel.

LPG (Liquefied Petroleum Gas)

Comprises a mixture of propane and butane gases stored in a pressurized liquid state. Commonly used for heating, cooking, and in some vehicles. Found in portable cylinders and larger tanks for industrial and commercial use.

CNG (Compressed Natural Gas)

Natural gas is compressed at high pressure (around 200-250 bar) for practical storage and transport.

Primarily used as a vehicle fuel, stored in high-pressure cylinders refillable at CNG stations.

In summary, LNG is a liquid form for large-scale applications, LPG serves various purposes in liquid form, and CNG is compressed for vehicle fuel.

Explosion-Proof Lights for LNG, LPG, and CNG Plants

For industries dealing with flammable gases or liquids like LNG, LPG, and CNG, the importance of explosion-proof lights cannot be overstated. AGC’s Explosion-proof lights are designed to withstand harsh conditions and prevent potential explosions caused by electrical equipment, including lighting fixtures.

|

|

|

|

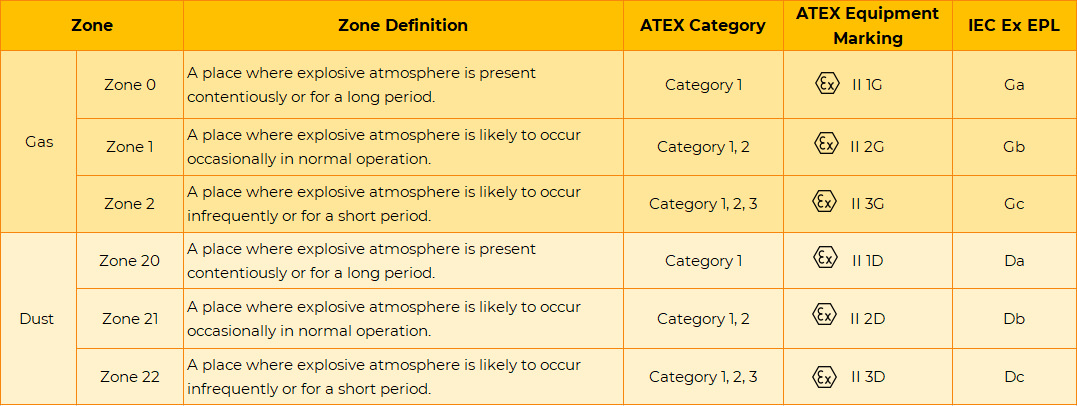

The implementation of explosion-proof lights in these plants depends on the hazardous area classification, typically divided into Zone 1 and Zone 2. Here is a table of references to the different hazardous locations and the required safety level of the equipment.

Certifications and Standards

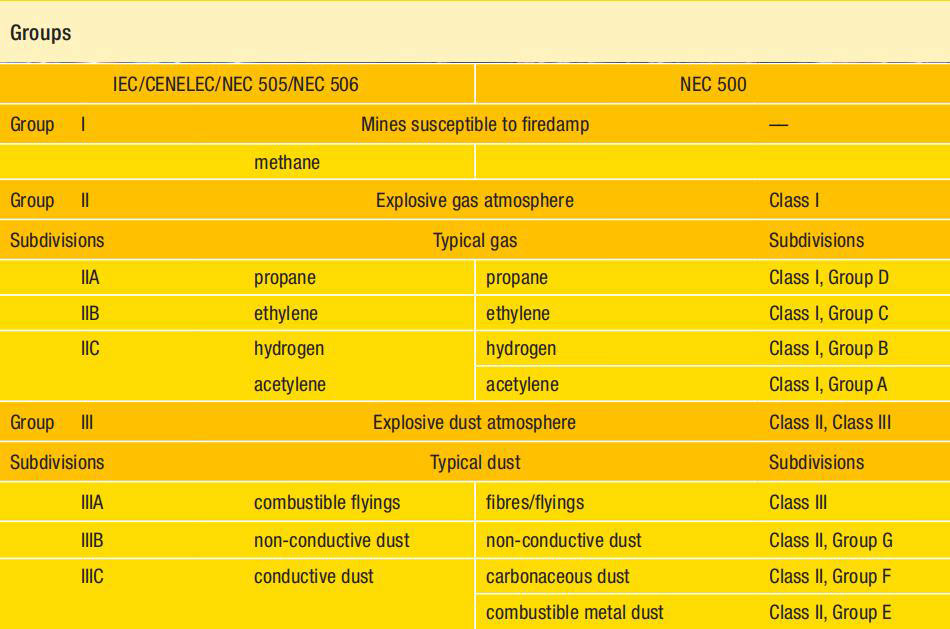

Lighting fixtures must meet specific standards and certifications from organizations like IEC, UL, and OSHA.

In the U.S., compliance with NEC requirements is crucial. Ensuring safety and preventing explosions in LNG, LPG, and CNG plants demand careful consideration of hazardous area classifications and adherence to certification standards.

At AGC, we understand the critical importance of lighting in LNG plants. That's why we offer specialized explosion-proof lights designed to withstand harsh environments. If you need reliable, high-quality lighting solutions for your LNG plants, choose AGC. Let us illuminate your LNG facility with our dependable lighting solutions.