Most people only concentrate on the quality of LED fixtures while ignoring the importance of installation. Bracket is one of the most critical parts of installation. Brackets allow the pole to attach the lighting fixture. They also play a significant role in safety by supporting fixtures, preventing fixtures from falling off and causing accident. However, the common brackets are unable to meet the needs of all industrial applications. Some of industrial plants require anti-vibration brackets while other plants ask for custom brackets for their existing rail system. AGC is a customer-focused LED industrial light manufacturer, we will make every effort to meet the needs of our customers. This post would show two examples of the custom brackets.

Example one: LHB13 custom ceiling mount bracket

Customer requirement:

Our customer wanted a ceiling mount bracket with one instead of two mounting points that apply to the rail system in the cold store. Another pair bracket should work. The hole of the additional pair brackets should be mounted to rail without suspension.

AGC solution:

To solve the problem, our engineer worked hard and designed the custom bracket for our customer. This type of bracket had a hole in the middle which enable it to mounted directly in the middle of rails without any suspension. Diagram of the solution is as followed:

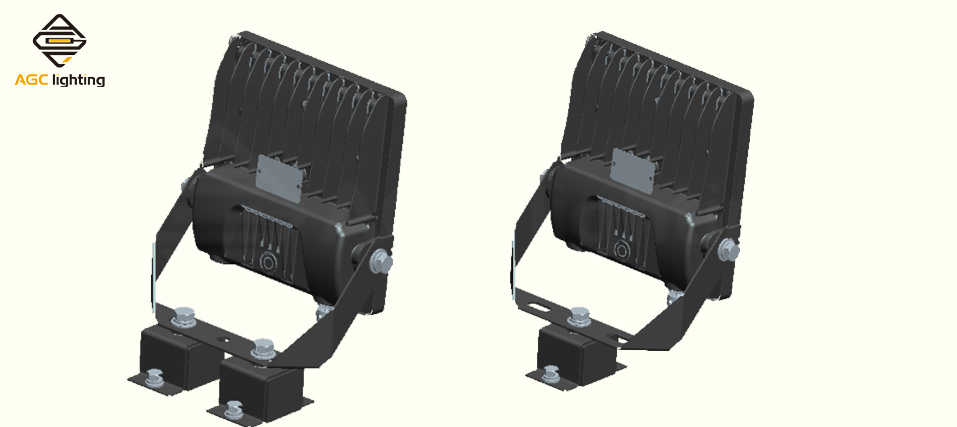

Example two: FL23 custom anti-vibration bracket

Customer requirement:

Customer wanted an extra anti-vibration bracket to avoid unnecessary fatigue and damage to LED lighting fixture. For application on machine or conveyor, customer wanted the bracket being introduced to ensure the safety of flood lights installation.

AGC solution:

We provided anti-vibration brackets that were compact and easy to install. The external rubber cover could prevent oil pollution and protect internal metal screw-in part from corrosion. This type of brackets were sufficient to meet a single cater to point load, reduce the natural frequency and fully realize vibration and nose reduction. Further more, each of bracket passed 3G-Vibration test before shipment. No visible mechanical damage and component loosen after test, the fixtures worked normally.