LED lighting performance is affected by heat. It is claimed that LEDs have a wide range of suitable temperatures from -30 °C to 60 °C, and the optimal temperature for LED lighting is 25 °C. High ambient temperature will degrade the efficacy of LED lighting performance, resulting in lower power conversion from electricity to light.

If high ambient temperature weakens the performance of LEDs, what about the low temperature? Would the performance of LED lighting improve in colder temperatures?

There are two main considerations for the performance of LED lights in cold weather: the capacity to start properly and operate stably. To figure out whether LED lights perform well in cold weather, we have to know how LEDs work and the relationship between temperature and LED lights' performance.

How does an LED work?

An LED (Light-emitting Diode) is a semiconductor device that emits light with current flows. A die is the active area of an LED. Plastic or ceramic housing encases one or many dies. When an LED is forward-biased, electrons are able to recombine with the electron holes, releasing energy in the form of photons. This effect is called electroluminescence.

The core of an LED is the wafer composed of P-type semiconductor and N-type semiconductor, with a transition layer between them called the PN junction. In the PN junction of some semiconductor materials, the injected minority carriers combine with the majority carriers will releasing the excess energy in the form of light. Therefore, LED is able to convert electrical energy directly into light energy. The color of the light is related to the energy required to release electrons. The more energy released, the shorter the wavelength of light emitted.

How cold weather affects LEDs' performance

LEDs start up normally in cold weather

The capacity to start lighting in cold weather is important for some areas. An LED is a semiconductor without an insulator or a conductor, which means free electrons in a negatively charged component transfer to holes in positively charged components with the help of electrical energy. Light is emitted when the forward activity happens. LEDs are warmed up by the current flowing through them.

Since LEDs rely on electronic drivers rather than heat to turn on, LEDs are able to start up in cold weather. Moreover, electronic drivers can be used even in -30 °C. Therefore, LED lights can perform well in cold weather.

Lumen output is not affected by cold weather

Unlike conventional lighting methods, LED lights create less heat. Junction point temperature and ambient temperature are therefore lower than conventional lights. Lower junction and ambient temperatures promote current conduction. Then the lumen output is improved due to less stress on the driver. As a result, cold weather will not affect the performance of LED lights in common conditions.

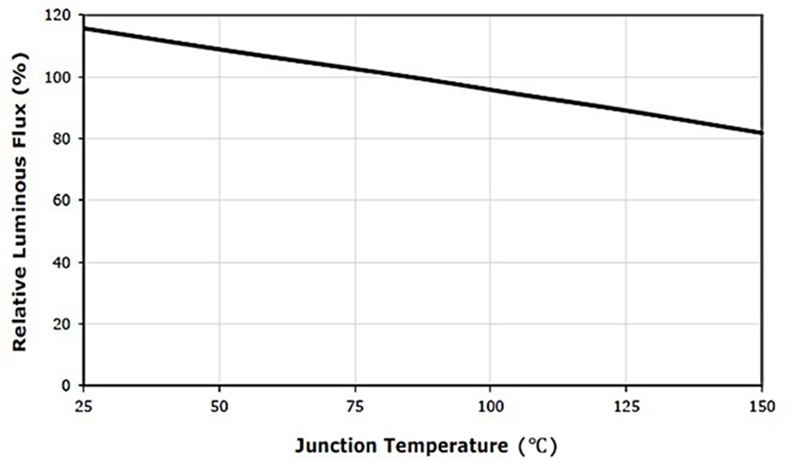

The following graph shows the relationship between junction temperature and relative luminous flux of an LED fixture. As shown in the graph, there is a steady decrease in relative luminous flux with the increase of junction temperature. In other words, colder temperatures will not affect LED lighting performance.

Considerations of LED lighting performance in cold weather

Except for LEDs, lighting performance in cold weather is also affected by materials, sealing, and electrical equipment of LED fixtures.

Materials of LED fixtures

LED lighting performance is threatened by the cold weather, as most materials of LED fixtures are greatly impacted by low temperatures and water. Thus, the material of LED fixtures is critical for LED lighting performance.

The components of LED fixtures should be made of high-quality material. For example, the glass is supposed to be unbreakable, allowing the LED fixture to withstand sudden temperature changes. Metal, aluminium, carbon steel, and plastic are widely used as the major materials of LED fixtures. They may be more brittle and decay due to the low temperature. Manufacturers use enclosure housing to protect the materials from the impact of low temperatures. Waterproofness and corrosion resistance are also important for the materials of LED fixtures.

Sealing of LED fixtures

Sealing should also be taken into account for the lighting performance in cold weather. Seals need to be poured and set at a temperature over 0 °C. It means it is difficult to seal in cold weather with the temperature lower than 0 °C. Low temperature may cause the distortion of LED fixture components, making the interior component suffer the risk to exposure.

Additionally, field installations are hard to achieve proper installations of seals due to the low temperature. To solve the problem, parts of LED fixtures are factory-sealed in advance, reducing the need to seal in cold temperature conditions. Factory-sealed fixtures increase the safety of the electrical parts of fixtures and make it easier for installation.

Electrical equipment of LED fixtures

Wires and cables are the electrical equipment to transfer electricity to LEDs for lighting. Because LEDs do not create much heat, snow and ice may cover the LED fixtures in cold weather and cause serious problems with lighting performance. Also, the driver requires heat to start up. The extremely low temperature makes it hard to work.

Except for snow and ice, LED fixtures are also faced with the risk of rain. Factors that were mentioned previously have a significant influence on wire and cable. Cables are recommended to be stored at a temperature of over 10 °C before installing. The heavy stress and low temperature of snow, ice, and rain damage the insulation on wire and cable, blocking the electricity transmission, possibly. In consequence, the installation of cables should be done slowly and carefully.

LED Lights can perform well in cold weather. Since LEDs do not need heat but electricity to turn on, they function normally in cold weather. Furthermore, the lumen output of LEDs is not affected by cold weather. LEDs create less heat than conventional lighting. Cold weather releases the stress on the drive and then improves the lumen output generally.

However, the Lighting performance of LED lights is not only related to LEDs, but also to the material, sealing, and electrical equipment of LED fixtures. Cold weather greatly impacts their performance. Material may be more brittle due to the cold weather, and it is hard to seal in cold weather.

Electrical equipment, such as wire and cable, is more likely to be damaged due to the cold weather. Choosing the LED fixtures that are typically designed for cold areas will yield twice the result with half the effort.