Environmental issues have become an extremely important thing in the economic development of every country. LED lighting, because of its energy-saving feature, has become a new favorite in the lighting industry. We all know LED lighting features with high efficiency, long lifespan, and cost-effectiveness. LED lighting has a broad application prospect and market.

However, the problem of heat dissipation of high-power LED luminaires such as stadium flood light, large plaza flood light, airport tarmac flood light, and port cargo center flood light, etc, limits the development of the power LED lighting industry.

If heat dissipation is not properly addressed, the temperature of LED lighting fixtures can rise significantly. This increase in temperature can reduce both the light efficacy and the lifespan of the LEDs.

In this paper, we will explore methods and technologies for minimizing temperature rise in high-power LED floodlights. Our discussion will focus on two key areas: the design of the lighting fixture itself and the selection of an appropriate driver for effective temperature control.

1. Reduce the temperature rise

Currently, heat dispatch methods of LED flood light mainly include natural convection heat dissipation, blower dissipation, heat pipe, and loop heat pipe, etc.

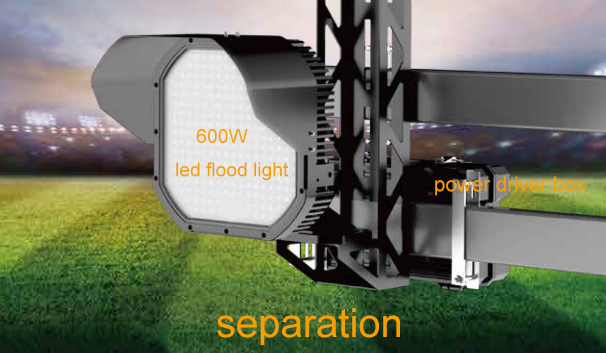

Separate the power driver from the LED flood light

Because the power driver originally will generate a certain amount of heat itself, which will increase the quantity of heat inside the LED luminaires. Adding up the heat that spills out of LED lighting fixtures themselves, the temperature inside the lighting fixture will be quite high.

At the same time, designing a power driver and lamp all in one will make the entire LED lamp operate in an uneven temperature environment for a long time. That is the end that is closer to the power driver will be hotter than the end farther away from the driver. All these factors will lead to damage and early light decay of luminaires, which will affect the service life of the lighting fixture.

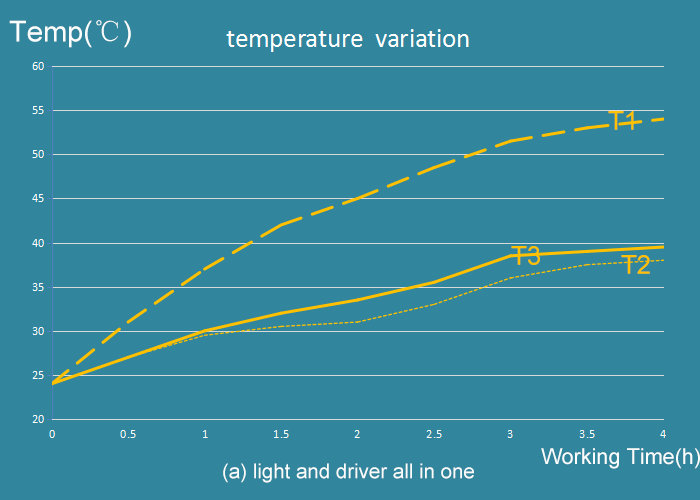

The following picture shows the variation curve of temperature inside of LED flood light with working time. T1 is the temperature at the place where the driver is placed; T2 is the temperature at a place far away from the driver; and T3 is the temperature at the center of light.

When light and driver are all in one, T1 is far higher than T2 and T3, that is, the temperature around the driver is far higher than the temperature of the light center and places where far away from the power driver as working time goes on.

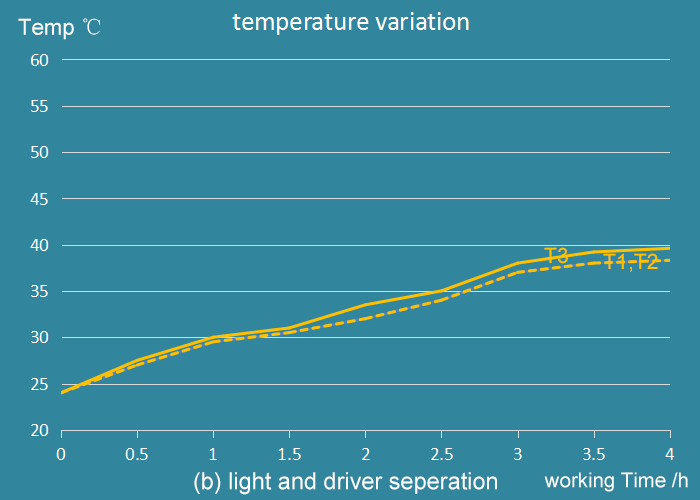

While the lamp separates from the power driver, the curves of T1 and T2 coincide. In other words, the temperature around the driver is the same as that of a place far away from the driver. T3 is slightly higher than T1 and T2, and the difference between them is not significant. The whole lamp, we mean inside of fixture, is in a stable, low, and relatively even temperature state. This shows, the temperature distribution of the whole lamp is very uniform when the light and power driver are installed separately.

Choose high-quality LEDs

The selection of LEDs also plays a key role in reducing the temperature rise. LEDs encapsulated by a material with high thermal conductivity and consistency can improve the internal heat dissipation property. Adopting a metal substrate with high thermal conductivity and high heat dissipation as the base tab of LEDs makes heat dissipation symmetrical, so that it can maximize the performance of heat dispatch.

Enlarge the heat radiating area

In addition, we can also increase the heat dissipation area of the heat sink, design a heat sink with better heat dissipation performance, and deform the structure of the heat sink to enhance the heat conduction efficiency.

Control temperature via power driver selection

When an LED flood light is working at rated power, the generated heat exceeds its heat dissipation capacity. Besides the method we mentioned above, we can also select a temperature-controlled power driver to limit the temperature rise.

When the temperature reaches some tipping point, the temperature control system of the power driver starts to work to appropriately reduce the output of the driver to achieve the purpose of limiting and reducing the temperature rise. When the temperature decreases, the LED flood light restores the original working state.

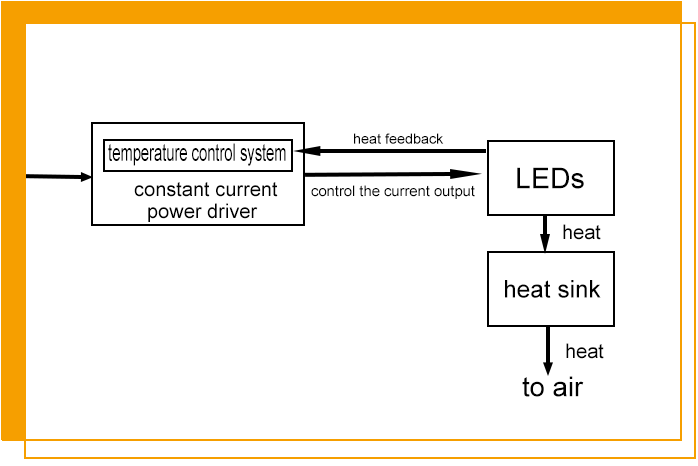

The theory of constant current power drive controlling the temperature rise

Constant current power driver realizes the temperature control of the LED flood light by controlling the output current of the drive. The following picture shows the theory of temperature control. The constant current is output to the high-power LED flood light through the power driver. The heat generated by LEDs is conducted to the heat sink by good thermal conductive materials and finally dissipates into the air.

When the environment outside goes against the heat dissipation, the temperature of LEDs will gradually reach the setup temperature of the temperature control system. The constant current power driver of the LED flood light will reduce current output after getting feedback, so as that achieve the goal of limiting and decreasing the temperature rise of LEDs.

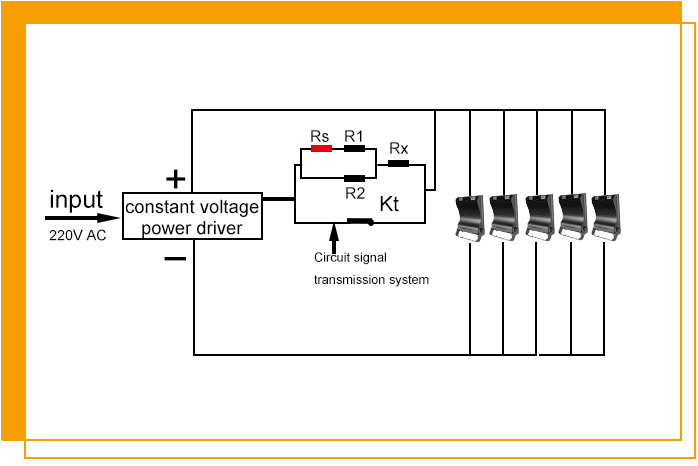

The theory of constant voltage power drive controlling the temperature rise

The constant voltage power driver controls the output voltage of the driver to realize the control of the LED flood light. It is roughly similar to the constant current driver. The difference is the controlled factor and the temperature control system circuit.

In the circuit signal transmission system, Rs is a positive temperature coefficient temperature-sensitive resistor; R1, R2, and Rx are ordinary resistors. And they work together to adjust the output voltage of the power driver to achieve the purpose of reducing temperature rise. The circuit signal transmission system is placed close to LEDs to sense the temperature.

Through the two methods above, we can effectively reduce the temperature rise of high-power LED flood lights. Once the temperature rises, surpassing the set temperature, the power driver will reduce current or voltage output under the condition of not affecting use so as that avoid lighting decay caused by overheat and service life shortening.