One of the key advantages of LED lighting is its long lifespan. Many advertisements claim that LED lights can last up to 50,000 or even 100,000 hours. That means, if an LED light runs 24 hours a day, a 50,000-hour lifespan would translate to about 5.7 years of continuous use.

However, in practice, not all LED lights perform as promised. While some maintain their brightness for many years, others begin to dim or fail much sooner than expected. So, do LEDs really last as long as advertised? Or are manufacturers overstating their performance?

To answer this, it's important to understand what these lifespan claims actually mean. In this post, we’ll look at how LED lifespan is measured and explore the key factors that affect how long an LED light truly lasts in real-world conditions.

What LED Lifespan Really Means

When manufacturers say an LED light lasts “50,000 hours,” they don’t mean it will stop working at that point. Instead, it refers to lumen depreciation, the gradual dimming of light over time.

For general lighting, the standard measure is L70, meaning the LED lights are considered to have reached the end of their useful life when their brightness drops to 70% of their original output. So, an L70 rating of 50,000 hours means the light is expected to retain 70% of its brightness after 50,000 hours of use.

This estimate is based on lab testing procedures like IES LM-80, which measures how LEDs maintain brightness over time, and IES TM-21, which projects long-term performance beyond the test period. Since full-life testing is impractical, these figures rely on data extrapolation, making it important to apply them conservatively in real-world designs.

LED Lifespan: Promise vs. Reality

In the LED industry, the widely advertised lifetime can create unrealistic expectations for both consumers and businesses. These claims are based on laboratory tests conducted under ideal conditions, such as a constant temperature of 25°C, stable voltage, and no environmental stress.

But in real-world settings, such perfect conditions are rarely achievable. Heat buildup, voltage fluctuations, poor ventilation, and improper installation are just a few of the many factors that can significantly shorten the actual lifespan of an LED light.

This is why there’s often a noticeable gap between marketing promises and the real-world performance of LED lighting.

5 Key Factors That Affect the Lifespan of LED Lights

The lifespan of LED lights is influenced by a range of factors, including material quality, component design, electrical efficiency, and environmental conditions. Among these, five key factors stand out as especially important.

1. Heat Management

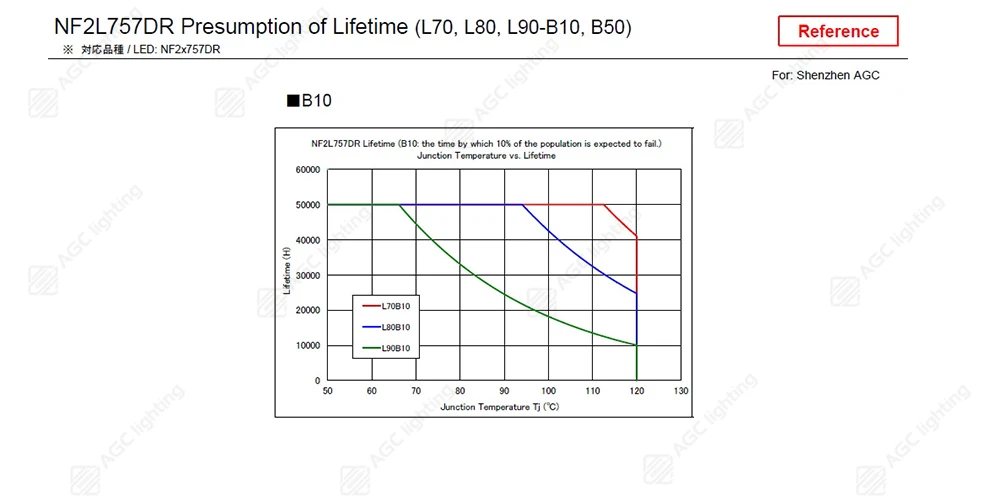

Temperature control is the single most important factor affecting the longevity of LED lights. For every 10°C increase in junction temperature, the LED’s lifespan is reduced by approximately 50%.

For example, our test results show that LEDs operating at a junction temperature of 85°C have an estimated L70 lifespan of only 25,000 hours, compared to 50,000 hours at 65°C.

High temperatures accelerate the degradation not only of the LED chip itself but also of other internal components. Prolonged exposure to heat can compromise the structural integrity and reliability of the entire fixture.

Heat management is challenging because it involves both internal heat generated by electrical inefficiency and external heat from the surrounding environment. To address this, effective heat dissipation is essential. This includes the use of high-quality aluminum heat sinks, optimized airflow design, and proper ventilation.

We offer high-temperature lighting solutions that incorporate these design principles. With efficient thermal control, these fixtures maintain performance and extend LED lifespan significantly.

2. LED Driver Quality

Did you know that around 80% of the electrical devices in a building require direct current (DC) power? LEDs are no exception. Although they operate on DC, most buildings supply alternating current (AC). That’s where LED drivers come in.

An LED driver is an essential electronic component that converts AC from the power grid into the DC that LEDs need. In addition to this conversion, it also regulates the current and voltage delivered to the LED to ensure stable performance.

However, factors like heat, voltage spikes from equipment startups, grid switching, and lightning strikes can cause driver failure. When a driver fails, the LED may flicker, operate erratically, or stop working altogether.

This makes driver quality a critical factor in overall LED system reliability and longevity. Even if the LED chips are long-lasting, pairing them with a low-quality driver, especially one rated for only a few years, can undermine the entire system's performance.

That’s why our lighting solutions are equipped with high-quality, durable LED drivers designed to support long-term use. For outdoor applications, our products also include surge protection to guard against power surges and lightning strikes, ensuring safety and reliability even in harsh environments.

3. Material and Manufacturing Quality

LED lights are made up of several critical components, including the LED chip, phosphor layer, lenses, and the overall fixture construction. Each of these plays a role in determining the product's performance and longevity. However, not all materials and manufacturing processes are created equal.

Take the example of the purple streetlights, which were caused by phosphor layer degradation. This highlights why both the materials used and the quality of manufacturing are essential to ensuring a long-lasting LED product.

Reliable LED lights require high-quality soldering, secure internal components, and durable housing. Unfortunately, it’s not easy for the average consumer to inspect or evaluate the internal build quality of an LED fixture. You can look for trusted indicators such as product certifications (e.g., CE, UL, RoHS), test reports, and long-term warranties.

At AGC Lighting, we make this process easier. As a leading manufacturer of industrial and outdoor lighting, we adhere to strict quality standards and offer long warranties to give you confidence that our products are built to last.

4. Environmental Conditions

When it comes to LED lighting, external environmental conditions play a significant role in performance and longevity, and the challenges go far beyond just high temperatures.

Extreme cold can affect the startup time and efficiency of LEDs, especially if the fixtures aren't designed for cold-weather environments.

Prolonged exposure to moisture can cause corrosion, particularly in fixtures that lack proper sealing or aren’t made from corrosion-resistant materials like low-copper aluminum.

In dusty environments, particles can settle on LED fixtures, forming an insulating layer that traps heat and leads to overheating.

Industrial environments often contain harsh chemicals like ammonia, chlorine, and solvents, which can degrade LED housings and internal components over time.

In areas like sports fields, lighting fixtures must also withstand impacts. Without proper durability, damage to fixtures can create safety hazards.

At AGC Lighting, we understand these diverse challenges and offer specialized lighting solutions tailored to each environment. For example, we provide corrosion-resistant fixtures for swimming pools, tunnels, and coastal areas; explosion-proof lights for hazardous locations such as oil refineries, paint spray booths, and grain processing plants; high bay lights with DIN 57710-13 ball impact resistance for sports facilities, ensuring safety and durability, etc.

5. Installations and maintenance

Installation and maintenance are often underestimated, but they are essential to ensuring the performance and longevity of LED lighting systems.

When LED lights are installed correctly, they are given enough space for proper heat dissipation. Without this, excessive heat can build up, reducing the lifespan of the fixture. In addition, a stable and appropriate voltage supply is critical.

Using the correct wiring helps prevent voltage surges or drops that could damage the LED components or cause performance issues.

Proper installation also supports optimal efficiency. For example, LED solar lights need to be positioned in areas free from shade and set at the correct angle to capture the maximum amount of sunlight. This directly impacts how much solar energy they can store and convert into lighting during the night.

Maintenance plays an equally important role. Over time, dust, dirt, and debris can accumulate on the surface or inside the housing of the light, which can trap heat and reduce efficiency. Regular cleaning ensures that heat can escape properly and that the light output remains consistent.