For the food processing industries like bakery and confectionery processing, dairy processing, fruit and vegetable processing, meat and poultry processing, seafood processing, grain and cereal processing, beverage processing, frozen food processing, sauces, dressings, and condiments processing, ready-to-eat and convenience foods processing, etc., when choosing suitable LED lights for them, there are several factors to consider to ensure the fixtures meet the specific requirements of the environment. Here are some key considerations:

Food Safety and Compliance

● Lighting should comply with food safety regulations and standards, such as NSF (National Sanitation Foundation) or FDA (Food and Drug Administration) guidelines.

● Lights should be designed for easy cleaning to maintain hygiene standards and prevent the accumulation of dirt, dust, or contaminants.

● Use food-grade materials that are resistant to corrosion, chemicals, and moisture.

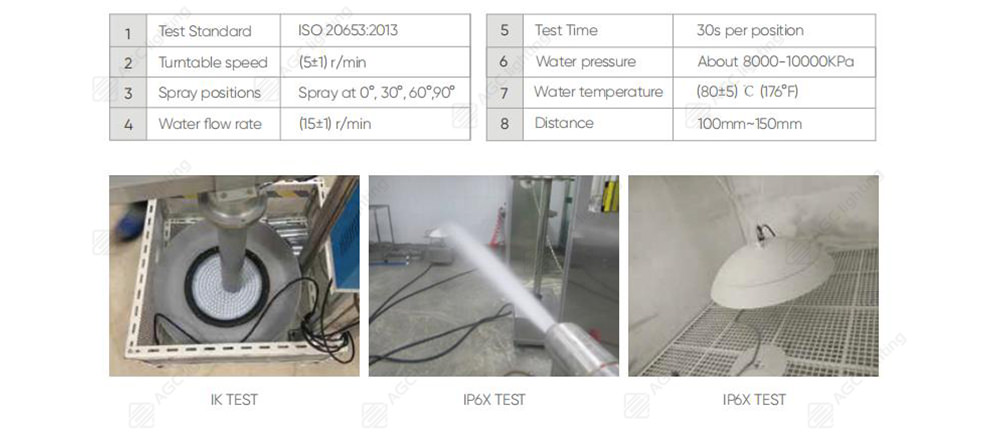

Usually, there are the following test standards:

High-Quality Illumination

● Lighting should provide adequate brightness and clarity for employees to perform tasks accurately, ensuring product quality and safety.

● Choose lighting fixtures with a high Color Rendering Index (CRI) to accurately represent colors and visually inspect food products. (e.g., 3500K for meat processing, 5000K for general food processing) are preferable.

● Consider the correlated color temperature (CCT) to create an appropriate lighting environment. For example, a color temperature (5000K-6500K) may be suitable for general processing areas, while a warmer one (3000K-4000K) can be used in packaging or inspection areas.

Energy Efficiency

● Opt for energy-efficient lighting solutions to reduce energy consumption and operating costs.

● Implement lighting controls, such as motion sensors or timers, to optimize energy usage based on occupancy and operational needs.

Just as above the Field Adjustable feature, one SKU meet different projects demands to have customers precisely covered, saving a lot inventory space.

Uniform Illumination

● Ensure even and uniform lighting distribution throughout the facility to minimize shadows and dark spots that could hinder visibility and compromise safety.

● Use a combination of overhead lighting fixtures, task lighting, and supplemental lighting to achieve uniformity and eliminate glare.

Durability and Safety

● Select lighting fixtures that have smooth surfaces, are durable, impact-resistant, and suitable for the specific environment, such as moisture-resistant or vapor-tight fixtures.

● Ensure electrical components and connections are properly sealed to prevent the entry of moisture, dust, or contaminants.

Take the below design as an example, smooth housing without fins, easy to clean by water, no front glass and exposed screws, avoid the risk of falling parts.

● Consider fixtures with protection ratings, such as IP (Ingress Protection) ratings that ensure protection against dust and water. This facilitates regular cleaning and reduces the risk of contamination.

Glare-Free Lighting

● Choose lighting fixtures that provide glare-free illumination to minimize eye strain and maintain a comfortable working environment.

Emergency Lighting

● Install emergency lighting systems to ensure visibility and safe evacuation during power failure or emergencies.

● Emergency lighting should comply with relevant safety regulations and provide adequate illumination for designated escape routes.

Heat Management

● LED lights in food processing areas should have effective heat dissipation mechanisms to minimize the impact on food products and the surrounding environment. Choose lights with proper heat sinks, thermal management systems, and low operating temperatures.

Supplier Reputation

● Source LED lights from reputable manufacturers or suppliers with experience in providing lighting solutions for the food processing industry. Check for customer reviews and ensure they offer warranties and after-sales support.

It is crucial to consult with lighting professionals, engineers, or specialists experienced in food processing facility lighting design to develop a comprehensive lighting plan that meets specific requirements, regulations, and industry best practices. By considering these factors and consulting with them, you can choose LED lights that are suitable for the food processing industry, providing optimal lighting conditions while meeting safety and hygiene requirements.

AGC team would always like to help you select suitable products for your market, improve your project or sales channel competitiveness, and grow your sales revenue. Please contact us now to get more recommendations.

Check out our Lighting guide for food factories: