From the moment an aircraft lands to the time it takes off again, the safety and efficiency of ground operations are absolutely critical. The large areas used for parking, loading, and servicing aircraft need precise, reliable lighting to keep ground crews safe and ensure smooth operations, day or night, in any weather.

At the core of these operations is one essential component: the airport apron lighting system.

For an apron lighting project, there’s a lot to consider. So today, we’re answering some of the most frequently asked questions about airport apron lighting design.

- What is airport apron lighting, and why is it important?

- What are the key standards and guidelines for apron lighting?

- What are the common challenges of apron lighting

- How do I determine the appropriate lighting levels

- What color lighting is best for the apron area

- Why glare matters and how to reduce it

- How often should apron lighting be inspected and maintained

What is airport apron lighting, and why is it important?

At an airport, the apron is the area where aircraft are parked, passengers board or leave the plane, and various ground services, like refueling, loading cargo, and maintenance, take place.

Because the apron is so busy, good lighting is essential for safety and efficiency. Without enough lighting, especially at night or during bad weather, it becomes difficult to see clearly. This increases the chances of accidents between planes, vehicles, or people.

The right apron lighting helps pilots safely move their planes into and out of parking spots, It also makes it easier and safer for workers to do their jobs, like helping passengers, loading cargo, and refueling planes.

What are the key standards and guidelines for apron lighting?

To make sure lighting does its job well, there are international and national standards that guide how apron lighting should be planned and installed. Two of the main organizations that set these guidelines are ICAO (International Civil Aviation Organization) and the FAA (Federal Aviation Administration).

These bodies provide detailed recommendations on things like how bright the lights should be, what color temperature to use, and how evenly the light should be spread across the apron.

It's important to note that ICAO’s guidelines are not laws; they're recommendations. However, most countries use these as a base and turn them into legal rules through their own aviation authorities.

Here are a few examples of local standards:

- United States: Follows FAA guidelines along with IES RP-37, which gives detailed specs for apron lighting.

- United Kingdom: Uses CAP 168, set by the UK Civil Aviation Authority (CAA).

- European Union: Follows EASA CS ADR-DSN.M.750, created by the European Union Aviation Safety Agency.

What are the common challenges of apron lighting

Airport apron lighting presents several challenges, including managing glare that can impair visibility for pilots and ground personnel, ensuring sufficient and even illumination to avoid accidents and facilitate safe operations, and dealing with the complexities and costs of maintenance for high-mounted fixtures exposed to harsh conditions.

Additionally, airports face the need to balance high lighting demands with energy consumption and adhere to stringent regulatory compliance, all while ensuring the durability of lighting systems in demanding environments and minimizing light pollution to surrounding areas.

How do I determine the appropriate lighting levels

Apron lighting should be both bright enough and evenly distributed to ensure safe and efficient ground operations at airports. The International Civil Aviation Organization (ICAO) sets out clear recommendations for how apron areas should be lit.

Here are the key requirements:

Aircraft Stands: At least 20 lux average illuminance is required. This level ensures that colors can be accurately seen and ground handling tasks can be performed safely. Lighting must be evenly spread, with a maximum average-to-minimum ratio of 4:1. At a height of 2 meters above the apron (roughly eye level for workers), vertical lighting should also average no less than 20 lux.

Apron Area: Minimum lighting level should be at least 50% of the average horizontal lighting provided on the aircraft stands. A maximum 4:1 ratio of average to minimum lighting across the area.

Between Aircraft and Apron Limit: This area should be lit to an average of 10 lux to ensure safe movement and visibility.

What color lighting is best for the apron area

For apron lighting, cool white light with a color temperature of around 5000K is the ideal choice. The apron is a busy and critical part of the airport where visibility and alertness are essential. Cool white light provides a bright, clear environment that helps pilots and ground staff stay alert, focused, and productive.

But the benefits don’t stop there. Cool white lighting also improves security camera performance by providing better contrast and detail, making it easier to monitor activity. It enhances facial recognition by clearly revealing facial features, which supports both safety and personal identification as well. Most importantly, the white light creates a stronger sense of safety for everyone working or moving around the apron area.

Why glare matters and how to reduce it

Glare happens when lighting is too bright, causing discomfort or making it harder to see. On airport aprons, bright lighting is essential for safe operations, but if not properly controlled, it can create glare that affects pilots, ground crews, and air traffic controllers. This can lead to reduced visibility and increased safety risks.

The ICAO doesn’t set exact glare limits, but it does stress the importance of minimizing glare. ICAO recommends that floodlights be positioned so that each aircraft stand is lit from at least two different directions. This helps reduce shadows and makes it easier to see clearly.

In Europe, glare control is usually based on EN 12464-2:2014. It is recommended that glare levels (measured by UGR) be below 50 on the apron.

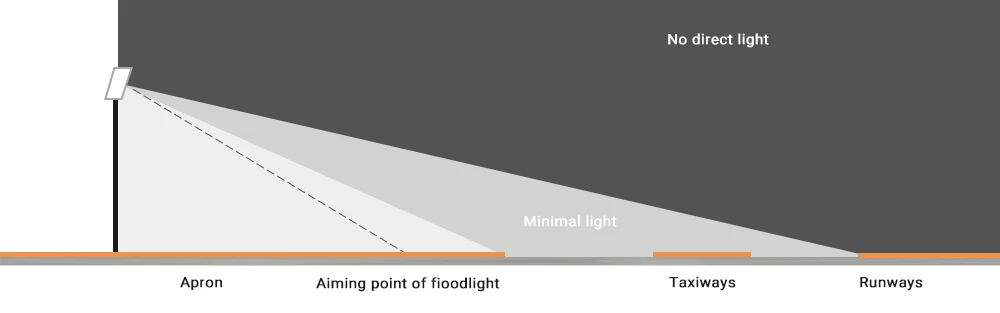

To reduce glare effectively, the way floodlights are installed and aimed is very important. Here are a few key points:

- Floodlights should be aimed away from the control tower and approaching aircraft whenever possible.

- Light shining above the horizontal line of the floodlight should be kept to a minimum.

- Floodlights may need louvres (shields) or special designs that spread light in a double-asymmetrical pattern, which helps reduce glare and control light direction.

- Floodlights should be installed at a height that is at least twice as tall as the eye level of the tallest aircraft using the apron.

How often should apron lighting be inspected and maintained

To make sure everything works properly, both regular visual checks and more detailed inspections are needed. A well-structured maintenance plan should include a combination of routine visual checks and more comprehensive inspections at scheduled intervals.

Daily visual checks are quick walk-around inspections to make sure all lights are working. Weekly or monthly inspections test the control systems, checking electrical circuits, and the lighting distribution and coverage. Quarterly or semi-annual inspections involve a full check of the lighting system, including electrical connections, mounting structures, wires and cables, and the control system.