|

Do you have LED lighting fixtures suitable for coastal area lighting? How to choose a lamp for it? Someone who has coastal area lighting project experience might be familiar with the image which show disaster sites where regular lamps that had only been used for two or three years were severely corroded. In the first image, the radiator and the ring are still stiff, while the driver is exposed. For the lamp bracket, it can be described as dulling with little or no visible corrosion of the coating, or higher that staining and/or color change due to deterioration of the coating (other than that of obvious base metal corrosion products). According to the test basis of ISO9227:2012. |

Why are lamps used in coastal areas corroded?

We know that the main components of radiators and brackets for outdoor lighting fixtures are aluminum alloys. In addition to low density, good mechanical properties, and strong electrical and thermal conductivity, aluminum alloy materials become the second largest metal material. However, like other metals, pure aluminum alloy materials have different corrosion resistance performances in nature (according to the types of pollutants contained, the atmospheric environment is generally divided into four types: rural atmosphere, urban atmosphere, industrial atmosphere, and marine atmosphere). It is generally believed that the area within 200m of the coastline can be called “the corrosive environment” of the marine atmosphere.

Lamps exposed to coastal areas for a long time are easily corroded by the marine atmosphere. This is because the ocean atmosphere contains ions with strong hygroscopicity, such as CaCl2 and MgCl2, etc., which make the ocean atmosphere have high humidity and salt ion content, and make it easy to form a thin liquid film on the metal surface. Generally, the closer to the coast, the higher the salt content in the atmosphere, and the combined effect of moisture and oxygen in the ocean atmosphere will further cause electrochemical corrosion of metal materials, including aluminum alloys. In low-latitude regions, where temperatures are higher, corrosion progresses faster than in cooler high-latitude regions. All in all, where the salinity is high, the humidity is high, and the temperature is high, the corrosion degree of the lamp is higher.

Are there any strategies for dealing with corrosion?

Of course, choose products with anti-corrosion materials, that is, products that can pass the long-term salt spray test. The following are some references to anti-corrosion technology.

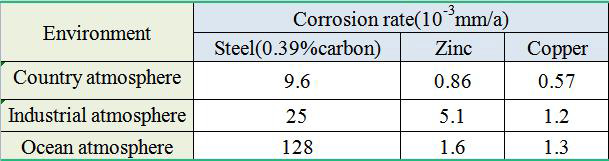

First of all, in terms of material selection, copper has the best anti-corrosion performance, followed by zinc, and finally steel. The difference in corrosion rates of different metal materials in rural atmosphere, industrial atmosphere and marine atmosphere in the table below can prove this conclusion. This also enlightens us on the fact that it is best to use copper-containing materials for outdoor lighting in coastal areas.

In addition, the process of metal processing also affects the anti-corrosion performance of lamps. For outdoor lighting products of the same material, their salt spray time is related to the treatment process. Spraying powder on raw materials can provide basic protection for lamps. After 2-3 years, the shells of lamps will be scrapped; electrophoresis + powder spraying can double the service life of lamps.

AGC anti-corrosion lighting solution

AGC has been skilled in the LED lighting sector for nearly 10 years, and we have worked out an LED flood light with 3000H salt spray test. Meanwhile, anti-corrosion flood lights for large ports and street lights for coastal areas are available.

FL35 is a corrosion-resistant flood light whose efficiency up is to 135lm/W, more energy savings, provided with 10KV/20KVsurge protection devices. Click on the image below to learn more about this lamp.

ST33 LED street light resists corrosion well due to its low copper content and a unique appearance that is free-tool maintenance oriented. It is 140lm/w and 160lm/w optional. Its high efficiency of 160lm/w makes it energy-saving.

AGC is specialized in LED industrial light and provides OEM and ODM service. Customization for outdoor lights with good resistance is available. If you have any questions, please contact us.